23 YEARS MANUFACTURING EXPERIENCE

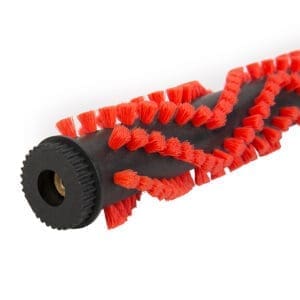

We offer comprehensive brush filament customization services, specifically designed and manufactured to meet the unique needs of our clients. Whether it’s choosing specific colors, unique cross-sectional designs, or functional improvements for particular applications, we can fulfill all your customization requirements.

Customization Process

1. Requirement Submission

Customers submit their customization requirements for brush filaments.

2. Sample Production

Based on the customer's specifications, we produce a sample of the brush filament.

3. Sample Confirmation

The sample is sent to the customer for approval.

4. Filament Production

Once the sample is approved, we initiate the custom production.

5. Inspection and Delivery

After production, the products undergo quality inspection and are then delivered to the customer.

Explore our quality firsthand: We are pleased to offer

free standard samples

Available for you to evaluate the craftsmanship

and material excellence we strive to deliver

and material excellence we strive to deliver

Customization Options

With 23 years of specialization in custom solutions, we are committed to manufacturing brush filaments that are precisely engineered to meet your specific product requirements.

1

Color

Support sample from customers, match colors according to Pantone color standard.

2

Diameter

Available in various diameters, our filaments cater to diverse application needs.

3

Cross-section

Choose from various cross-sectional shapes for optimal performance.

Wave

Triangle

Pentagon

Hollow

Round

Cross

Split-end

4

Functions

Enhance your product with functions for diverse industry needs.

Flame-Retardant

Anti-static

Negative-ion

High-Temperature-Resistant

Acid-and-Alkali-Resistance

Anti-Bacterial

Anti-ultraviolet

Conductive

Binchotan